Go Thicker and Wider to add Wear Life!

Equipment Blades can take OEM part numbers and have them manufactured in thicker and wider profiles to add more material to your bucket edges or grader blades. By adding more material you can spend less time changing out edges. Going thicker and wider works great in concrete scraping applications like snow removal or farming.

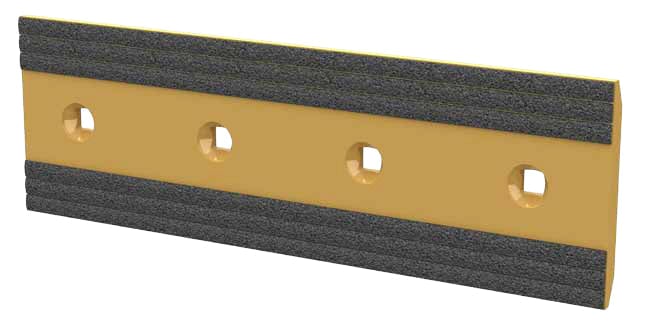

Add Carbide to Increase the Wear Life!

Equipment Blades has custom carbide options to extend the wear life of your cutting edges.

Grader Blades - Carbide Grader Blades are a great choice for any low impact, high abrasion application. By adding carbide to your grader blades you are not only extending the wear life of the grader blade, you are also reducing the number of blade changes, and decreasing blade crowning. You can add carbide to the surface of the grader blade as well as a solid carbide insert milled into the blade. Adding carbide inserts to grader blades extends the wear life significantly. Check out our double carbide grader blades that have a carbide insert in addition to the carbide surface facing for extreme wear life.

Snow Plow Blades - Not only can you add custom carbide to your grader blades, you can also get carbide snow plow blades. We have hundreds of customers proving that carbide snow plow blades add more value to their fleets. Carbide inserts are brazed into a milled slot in the steel blade to extend the life of the blade. Carbide inserts are extremely hard material that will resist wear by an estimated 10-15 times over steel blades. Equipment Blades also offers a line up of advanced carbide snow plow blades that will outlast the best of the best snow plow blades. Check out the advanced snow plow blades line up on our website.

Loader / Dozer / Excavator Bucket Edges - Equipment Blades can also add custom carbide impregnation to the surfaces of your bucket edges. This works well in high abrasion applications like gravel, mining, dirt-work, etc. We have customers greatly reduce the number of blade changes by upgrading to carbide loader edges. One customer who specialized in mining work was going through a standard set of Volvo edges every month. Once he upgraded to the carbide Volvo loader edges he got 5+ months out of one set. He has been saving big money since he switched.

Whether you are looking to go thicker & wider or adding custom impregnation to your blades, we have you covered! Get longer wear life out of your cutting edges!

If you have questions about custom carbide options contact us today!