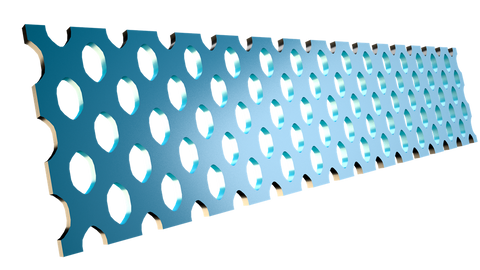

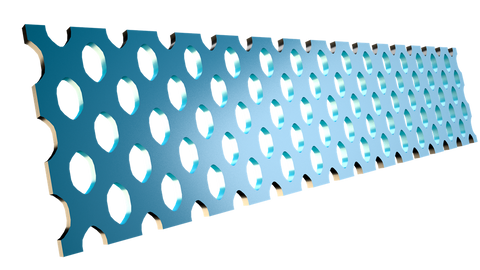

Are you tired of fighting your road grader and standing on your hydraulics to get the dang things to cut? You don't have to anymore. There are cutting edges out there that do exactly what they say they will do, cut! The Sharq Edges Cutting System, a blue colored cheese grader looking blade, makes the operator's life much easier by:

- Easily cutting through all potholes, wheel ruts and washboards.

- Requiring little to no down pressure.

- Drawing up more road materials than any other blade and evenly distributing the fines across the road.

- Allowing the operator to shift up, grab a couple extra gears and back off on the throttle (maintain optimum speed of around 5 MPH). It takes very little power to cut with this system.

Sharq Road Grader Blades Slice Right Through Packed Gravel

With the Sharq cutting edges, you no longer have to stand on your hydraulics in order to cut below the road surface. In fact, these road grader blades require almost no down pressure. They are designed in a way that allows the road material to pull the blade under the surface instead of the operator pushing the blade into the surface. With this reduced pressure, you will have a much smoother ride, cause less stress on the machine, and consume less fuel.

Blade Design and Cutting Technique

Sharq blades are designed to operate a little differently than your typical road grader blade. The Sharq edges operating method requires the top of the moldboard to be rolled all the way back with the cutting edge all the way forward or close to 55%. The idea is to sharpen the blade at 55 degrees. When you want more material and you want to cut, shape and fix, then you can roll the moldboard forward about 15 degrees to about a 70 degree angle.

Watch and feel your moldboard fill up with material. You simply feather the moldboard back and forth from 55 degrees to re-sharpen and then back to 70 degrees to cut. You repeat this process whenever your blade dulls. No more up and down with the hydraulics. With these funny looking blue steel blades, you adjust the angle to keep the edge sharp. The idea is to keep a sharp point on the blade which will ultimately increase the wear life of the cutting edge. This method is why these blades out wear traditional blades by 2- 4 times.

Sharq P-300 Grader Cutting Edge

Draw Up More Road Material

One of the greatest benefits of a Sharq cutting edge is its ability to cut through washboards and potholes and draw up old material. It is frustrating to have to make multiple passes just to cut through a damaged road and bring up enough material to fix the road road. This is not a problem with the Sharq Edges road grader blade system; you will typically only have to make one pass depending on the road. Operators often comment on how much more material these blades bring up. You will no longer have to rely so much on the material you pull from the shoulder! Many roads slated to have additional gravel added often times won't need to add more gravel saving thousands and thousands of taxpayer dollars.

See for yourself how the Sharq Edges, blue road grader blades operate! This video will give you a nice 8 minute overview of the Sharq edges system. Winter or summer, this cutting edge cuts through ice and gravel. The ultimate universal cutting edge system.